Process Control

Dupont Environmental Treatment (DET) Uses Isco/Stip On-line BOD Analyser for Monitoring and Control of Wastewater Treatment, B Cousar(Dupont), D Le Blanc (Isco)

Summary:

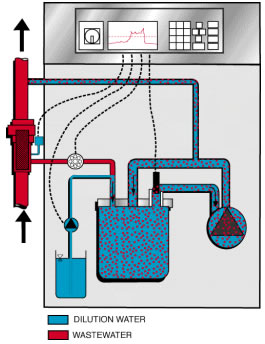

Treatment plant performance will improve and costs will decrease when on line instruments such as the Isco/Stip Model BIOX 1010 , continuous, on-line BOD analyzer are used to both minimize short term load variability and adjust the plant to actual conditions.

The rate of learning and depth of understanding of the treatment plant processes by all involved in waste water treatment was aided significantly when on line BOD data was made available. This directly resulted in improved management and lower discharge levels from a WasteWater Treatment Plant.

On-line measurement of Organic Carbon in a "Cocktail" of a Petrochemical waste water - M Chioetto

Summary:

Knowledge of the quality of both waste water and purified water is a fundamental element to a successful treatment process, as well as any industrial process in the petrochemical industry. This is possible because of the availability of reliable on line analyzers which use proper instrumental techniques for a speedy determination of the organic load in a liquid effluent, as opposed to the time consuming laboratory techniques required by BOD or COD determination made from grab samples.

Organic Load Monitoring in the Biological De-nitrification Process as performed in a plastic Fibre chemical plant - M Chioetto

Summary:

To evaluate the pollution level in industrial waste water it is important to know the exact content of organic substances. The evaluation of organic substances is traditionally made by analytical methods based on oxygen consumption in a chemical oxidation reaction (mg/L of O 2 as COD) or in a biochemical oxidation reaction (mg/L of O 2 BOD) of such organic substances. Instruments which carry out the direct measurement of pollutant charge by means of Total Organic Carbon (TOC) content are becoming more and more widespread.

These analyzers are able to use different technology, particularly in the oxidation stage. The one chosen by the plastic fibre chemical plant is based in the low temperature oxidation of the organic material promoted by UV light. This technique was preferred because it does not allow corrosion or poisoning of the catalyst in the way that the high temperature combustion technique does.