Energy Reduction through Optimizing Nitrification

Feed-forward and feedback control of nitrogen and/or phosphorus removal plants using online analysis and automated controls is now a possibility.

Design and operation of nitrogen removal strategies can be optimized with real-time measurement of parameters such as:

Feed-forward control can improve treatment efficiency and also significantly reduce running costs.

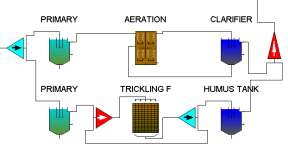

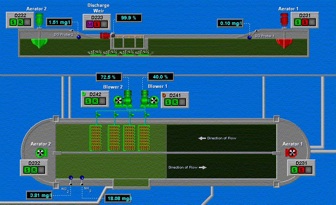

Control of F:M ratios, greater control over aeration zones, and reduction of

sludge bulking in final clarifier are all key factors - examples are the process control of an Oxidation Ditch.

- Blower control under feed-forward control using online BOD at the inlet

- Also in-situ DO , NH4, and NO3 sensors

Process design

Increasing use of sophisticated software models such as GPS-X highlight the need for improved real time data. A software model is only as good as the data fed into it. Reliable on-line sensors can generate a dynamic, 24 hour picture of inputs and outputs.