Wastewater Solutions

Wastewater presents special challenges for monitoring equipment and Envitech has been at the forefront of introducing innovation and added value into the UK Market

Envitech introduced the first genuine On-line BOD monitor for wastewater in the UK back in 1987 , followed a range of Toxicity, COD, and TOC analysers. Rather than being just adapted from clean water applications, design features are centered around the vagaries and challenges of wastewater including large sample tubes and ease of maintenance. Our range of analysers have been used for Airport Runoff Monitoring, Product Loss, Intake Protection, and various wastewater process optimisation applications.

Historically, cabinet on-line analysers suffered from high maintenance and running costs, particularly for municipal applications - hence in early 1990's Envitech introduced a novel in-situ analyser solution to the UK market. The PBS Ammonia Process Buoy is still the only autocalibrating ammonia analyser that doesn't require sample pumps, filters or expensive Kiosks - significantly reducing installation costs. In a further drive to reduce wastewater operational costs, Envitech introduced an Optical DO sensor in 1995 that has no replacement consumables such as caps, electrolyte and comes with a 5 year warranty.

Envitech has been chosen as a framework or preferred supplier for a range of UK water companies including:

- Southern Water

- Severn Trent

- Yorkshire Water

- South West Water

- Wessex Water

- Welsh Water

- Northumbrian Water

We can supply a range of instrumentation for monitoring final effluent or process wastewater, holding lagoons or natural watercourses. We supply online, in-situ or hand-held instruments

and waste water test kits for a range of different parameters.

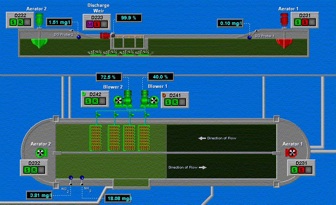

Examples of typical solutions are: